クライスラーオイルポンプポンプ構造

クライスラーオイルポンプポンプ構造

プロセスの使用における任意の機械設備は疑問であり、クライスラーオイルポンプは、多くの場合、それが突然開始することができなかったという質問を提示し、この状況に遭遇し、緊張しないでください、我々は最初にその性能、構造と原理を理解する必要があります開始します。クライスラーオイルポンプの構造の詳細な理解は、原理は、クライスラーオイルポンプの出現にクライスラーオイルポンプの使用で分析することができます、そして、クライスラーオイルポンプの故障を排除するための問題の出現のために。

クライスラーのオイルポンプは、保管時間が長すぎると、それが開くことにつながります。その実用化では、一般的にこの状況に遭遇するでしょう。実際には、クライスラーのオイル ポンプは、液体の輸送を完了するために高圧部屋および低圧部屋の形成が、作動するためにポンプ部屋の一対の噛み合いギヤを通した、外部の噛み合いポンプです。そして、この外部ポンプとポンプの容積は、潤滑するためにそれら自身の液体によって輸送され、長時間ではないにしても、残りの液体がパイプラインに流れた後のポンプチャンバー。もう一度クライスラーオイルポンプを始動すると、困難な状況が生じます。この場合、手やパイプを反対方向にクランプする限り、数回回転させたり、輸入を開いたりして液体に加えることができます。

クライスラーポンプのスイッチと電源の問題も故障の原因です。クライスラーオイルポンプは、回路が滑らかでない場合、開くことは不可能である、エネルギーを生成するために機械的な力によって駆動されます。回路を見るときは、まずコネクタが緩んでいることを確認し、これらの緩いコネクタをしっかりと挿入して、適切に通電されていることを確認します。ジョイントに加えて、また、そのラインが混雑していないのを見て、操作プロセスは、フリップスイッチ内のライン測定器にラインを測定するためにラインをテストするために使用することができますラインが滑らかであるかどうかを判断できます、すべてのプロセスはシンプルで迅速です。詳細な解析の詳細を突き止め、最良の治療結果が得られることを意図して求めます。

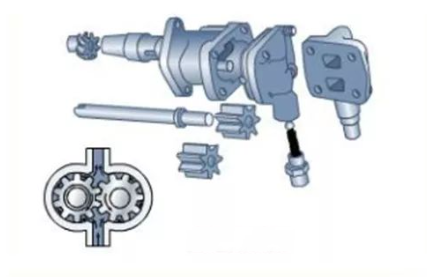

クライスラーポンプ内の部品の損傷も、その頻繁な問題の重要な理由です。さまざまなコンポーネント間のギャップの非常に厳しい要件を持つクライスラーオイルポンプアクセサリーは、アクセサリーの状況がクライスラーオイルポンプの動作に影響を与えると、互いに関連しています。ユーザーの失敗は、メンテナンススタッフに実際の状況の実際の状況のギアを締めるために、私たちは故障に応じて実際の状況を伝える必要があります、そうすればメンテナンス担当者は迅速にトラブルシューティングを行うことができます。または、障害を見つけるための保守担当者は、そのプロセスに多くの時間とエネルギーを費やし、さらにはその瞬間の核心を見つけるためにその日または数日でさえも必要とします。まず、ギアポンプが異物に落ちないようにしてから、インポート前にフィルターを取り付けます。ギアポンプの問題では、クライスラーオイルポンプの専門のメンテナンス担当者がタイムリーに電源を切るために、人員と機器の安全を確保するために交換部品を開け、清掃し、表示し、修理し、最終的には組み立てられたさまざまなコンポーネントを確保します。特に、内部係合クライスラーオイルポンプアセンブリは、クライスラーオイルポンプの外部メッシュよりも複雑で、コンポーネントには内部および外部ローター、シャフト、三日月板、ベアリング、ブラケット、シール、ポンプなどが含まれます。クライスラーオイルポンプの購入で、定期的なメンテナンス後にクライスラーオイルポンプが最高の動作状態にあることを確認するためのユーザー。

次に、理由の流れ。ギアポンプの入口流量が不足しているため、ポンプのキャビテーション現象が発生し、主にクライスラーポンプの吸引が条件に満足できないため、通常はこの状況がパイプラインの状態によるものであるため、ノイズが発生します。クライスラーオイルポンプインレットパイプラインが液体表面に完全ではありません。または、インポートパイプラインが長すぎて、吸気口が不十分であるために吸引高さを超え、ノイズが発生します。